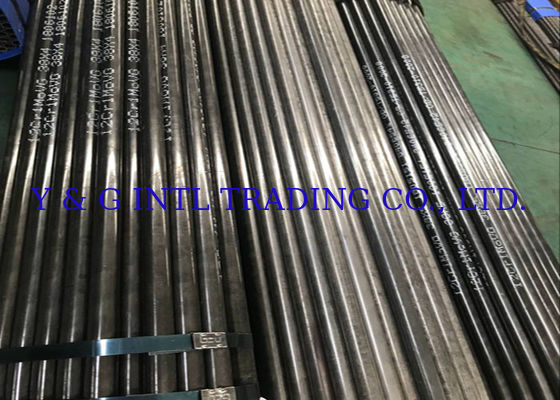

GB/T8162 ASTM A519 JIS G3445 DIN2391 ST52 Seamless Carbon Steel Tubing , and Alloy Steel Mechanical Tubing , OD 6~1200mm

Product Standard: GB/T8162 GB/T816,GB/T3093, ASTM A519, DIN2391, JIS G3445, JIS G3454

Main steel grades:

GB/T8162: 10,20,35,45,16Mn,12CrMo,15CrMo,20CrMo,30CrMo,35CrMo,42CrMo, 50CrVA,35CrMnSiA

GB/T8163: 10,20,Q295,Q345;

GB/T3093: 20A

DIN2391: 1010/1020/1035/1045, st35, st45, st52

JIS G3445: STKM 11A/B, STKM 13A/B, STKM, 15A/B

JIS G3454: STPG370, STPG38, STPG42

Chemical Requirements & Mechanical Properties:

| Standard |

Grade |

Chemical Composition(%) |

| C |

Si |

Mn |

P |

S |

Cu |

Ni |

Mo |

Cr |

V |

| GB/T8162 |

10 |

0.07~0.14 |

0.17~0.37 |

0.35~0.65 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

/ |

≤0.15 |

/ |

| 20 |

0.17~0.24 |

0.17~0.37 |

0.35~0.65 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

/ |

≤0.25 |

/ |

| 35 |

0.32~0.40 |

0.17~0.37 |

0.50~0.80 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

/ |

≤0.25 |

/ |

| 45 |

0.42~0.50 |

0.17~0.37 |

0.50~0.80 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

/ |

≤0.25 |

/ |

| Q345 |

0.12~0.20 |

0.20~0.55 |

1.20~1.60 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.25 |

/ |

≤0.25 |

/ |

| 15CrMo |

0.12~0.18 |

0.17~0.37 |

0.40~0.70 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.30 |

0.40~0.55 |

0.80~1.10 |

/ |

| 12Cr1MoV |

0.08~0.15 |

0.17~0.37 |

0.40~0.70 |

≤0.035 |

≤0.035 |

≤0.25 |

≤0.30 |

0.25~0.35 |

0.90~1.20 |

0.15~0.30 |

| Standard |

Grade |

TS(MPa) |

YS(MPa) |

Elongation(%) |

| GB/T8162 |

10 |

≥335 |

≥205 |

≥24 |

| 20 |

≥390 |

≥245 |

≥20 |

| 35 |

≥510 |

≥305 |

≥17 |

| 45 |

≥590 |

≥335 |

≥14 |

| Q345 |

≥490 |

≥325 |

≥21 |

| 15CrMo |

≥440 |

≥295 |

≥22 |

| 12Cr1MoV |

≥490 |

≥245 |

≥22 |

Application: For engineering machinery structure, automobile, motorcycle, diesel engine fuel

injection system and the other parts manufacturing.

Delivery status: Annealed, normalized, normalized+Tempered, etc.

Inspection and Test: chemical composition test, mechanical properties test(tensile, yield, elongation), process properties test(flatting, flaring, bending, hardness, impact, etc.), appearance and size test, non-destructive inspection test, hydrostastic test.

Surface treatment: oil impregnation, paint, passivation, phosphating, shot blasting etc.

Packing: Exporting package/wooden box /as requirement.

Mark: As required.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!