Product Description:

Nickel Alloy Tube

The Nickel Alloy Tube is a highly versatile and durable product, designed to meet the demanding requirements of various industries. It is made from a special type of nickel alloy known as INCONEL 600, which is known for its high strength and resistance to extreme temperatures and corrosive environments.

Applications

The Nickel Alloy Tube is widely used in the chemical processing, aerospace, and power generation industries. Its exceptional resistance to corrosion makes it an ideal choice for handling harsh chemicals and corrosive environments in chemical processing plants. The aerospace industry also relies on this product for its high strength and reliability in extreme conditions. In the power generation industry, the Nickel Alloy Tube is used in high-temperature applications, such as boilers and heat exchangers.

Technology

The Nickel Alloy Tube is manufactured using various advanced technologies, including hot forming, cold rolling, and forging. These processes ensure the highest quality and dimensional accuracy of the tubes, making them suitable for critical applications. The hot forming process involves shaping the metal at high temperatures, while the cold rolling process involves passing the metal through a series of rollers to achieve the desired thickness. Forging is a process of shaping the metal by applying compressive forces, resulting in a stronger and more durable product.

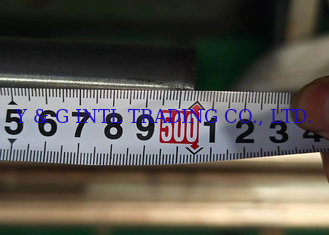

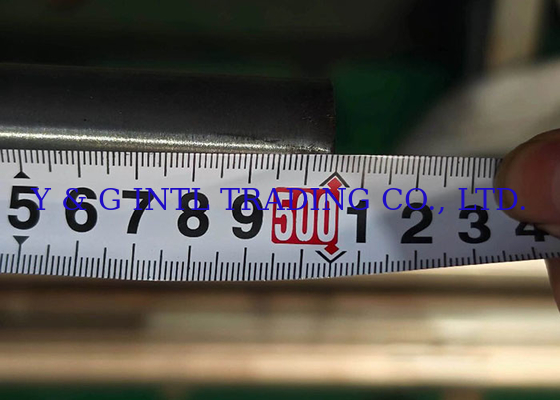

Size

The Nickel Alloy Tube is fully customizable, allowing for a wide range of sizes to meet the specific requirements of different applications. This flexibility makes it a popular choice among various industries, as it can be tailored to fit their unique needs.

Alloy

The Nickel Alloy Tube is made from a specific type of nickel alloy known as INCONEL 600. This alloy is composed of nickel, chromium, and iron, and is known for its exceptional strength, toughness, and resistance to high temperatures and corrosive environments. It is a popular choice for critical applications in various industries due to its superior properties.

Package

To ensure the safe transportation and storage of the Nickel Alloy Tube, it is packaged in a sturdy wooden case. This packaging method provides protection against damages during transit and ensures that the tubes remain in excellent condition until they reach their destination.

Key Features:

-

ASTM B165 compliant

-

ASTM B165 Monel 400

-

Seamless

-

High temperature resistance

Features:

-

Product Name: Nickel Alloy Tube

-

Alloy: INCONEL 600

-

Shape: Round

-

Steel Grade: Inconel 600

-

Secondary: Non-secondary

-

Technology: Hot Formed, Cold Rolled, Forging

-

Monel 400

-

OD12.7-508MM

-

WT: 0.8-25MM

Technical Parameters:

|

Testing Method

|

100% ET

|

|

Technology

|

Hot Formed, Cold Rolled, Forging

|

|

Dimension

|

6-127mm*1-30mm

|

|

Keywords

|

Inconel 718 Nickel Alloy Tube 1mm

|

|

Size

|

Customizable

|

|

Melting Point

|

1455°C

|

|

Alloy

|

INCONEL 600

|

|

Secondary

|

Non-secondary

|

|

Steel Grade

|

Inconel 600

|

|

Shape

|

Round

|

|

ASTM Standards

|

ASTM B165, ASTM B165 Monel 400, ASTM B165 Inconel 825

|

Applications:

Nickel Alloy Tube - Y&G

High Quality Tube for High Temperature and Corrosive Environments

Y&G's Nickel Alloy Tube is a top-of-the-line product, perfect for applications that require resistance to high temperatures and corrosive environments. Made from the highest quality ASTM B165 Monel 400 alloy, this tube is sure to meet and exceed your expectations.

Brand Name: Y&G

When it comes to Nickel Alloy products, Y&G is a trusted and reliable brand. Our commitment to quality and customer satisfaction sets us apart from the competition.

Place of Origin: SHANGHAI

Made in SHANGHAI, our Nickel Alloy Tube is manufactured in a state-of-the-art facility that adheres to strict quality control standards. This ensures that every tube that leaves our factory is of the highest quality.

Steel Grade: Inconel 600

Our Nickel Alloy Tube is made from the renowned Inconel 600 steel grade. This steel is known for its superior strength, resistance to corrosion, and ability to withstand high temperatures.

Applications: Chemical Processing, Aerospace, Power Generation

Our Nickel Alloy Tube is highly versatile and can be used in a variety of industries. Its resistance to corrosion and high temperatures makes it ideal for Chemical Processing, Aerospace, and Power Generation applications.

Alloy: INCONEL 600

The use of INCONEL 600 alloy in our Nickel Alloy Tube ensures that it can withstand harsh conditions and maintain its structural integrity. This alloy is highly resistant to corrosion, making it suitable for a wide range of environments.

Finish: ANNEALED & PICKLED

Our Nickel Alloy Tube is finished with an ANNEALED & PICKLED process, which involves heating the tube and then dipping it into a pickling solution to remove any surface impurities. This results in a clean, smooth surface that is free from defects.

Corrosion Resistance: High

One of the key features of our Nickel Alloy Tube is its high corrosion resistance. This makes it an ideal choice for applications where exposure to corrosive substances is a concern.

Experience the Quality of Y&G's Nickel Alloy Tube

In conclusion, Y&G's Nickel Alloy Tube is a superior product that is perfect for high temperature and corrosive environments. With our commitment to quality and use of high-grade materials, you can trust that our tube will meet and exceed your expectations. Contact us today to learn more about our products and how we can meet your specific needs.

-

Nickel Alloy Tube

-

ASTM B165 Monel 400

-

Seamless

-

Corrosion Resistance

-

High Temperature

-

Chemical Processing

-

Aerospace

-

Power Generation

-

Y&G

Customization:

Customized Service for Nickel Alloy Tube - Y&G

Brand Name: Y&G

Place of Origin: SHANGHAI

Corrosion Resistance: High

Steel Grade: Inconel 600

Shape: Round

Keywords: Inconel 718 Nickel Alloy Tube 1mm, Monel 400, THK1-30MM, SMLS, ASTM B163/B165

Package: Wooden Case

Packing and Shipping:

Packaging and Shipping

Our Nickel Alloy Tube is carefully packaged to ensure safe and secure delivery to our customers. Each tube is wrapped in protective plastic and placed in sturdy wooden crates for added protection.

For international shipments, we use air or sea freight depending on the customer's preference and urgency of delivery. Our team works closely with trusted shipping partners to ensure timely and efficient delivery of our products.

Upon arrival, our customers can expect their Nickel Alloy Tube to be in pristine condition and ready for immediate use. We take great care in packaging and shipping our products to maintain the highest quality standards.

FAQ:

-

Q: What is the brand name of this product?

-

A: The brand name of this product is Y&G.

-

Q: Where is this product manufactured?

-

A: This product is manufactured in SHANGHAI.

-

Q: What is the material of this product?

-

A: This product is made of Nickel Alloy.

-

Q: What is the maximum temperature this product can withstand?

-

A: This product can withstand temperatures up to 1000 degrees Celsius.

-

Q: What is the minimum order quantity for this product?

-

A: The minimum order quantity for this product is 100 pieces.

-

Q: Can this product be customized?

-

A: Yes, this product can be customized according to customer's specific requirements.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!